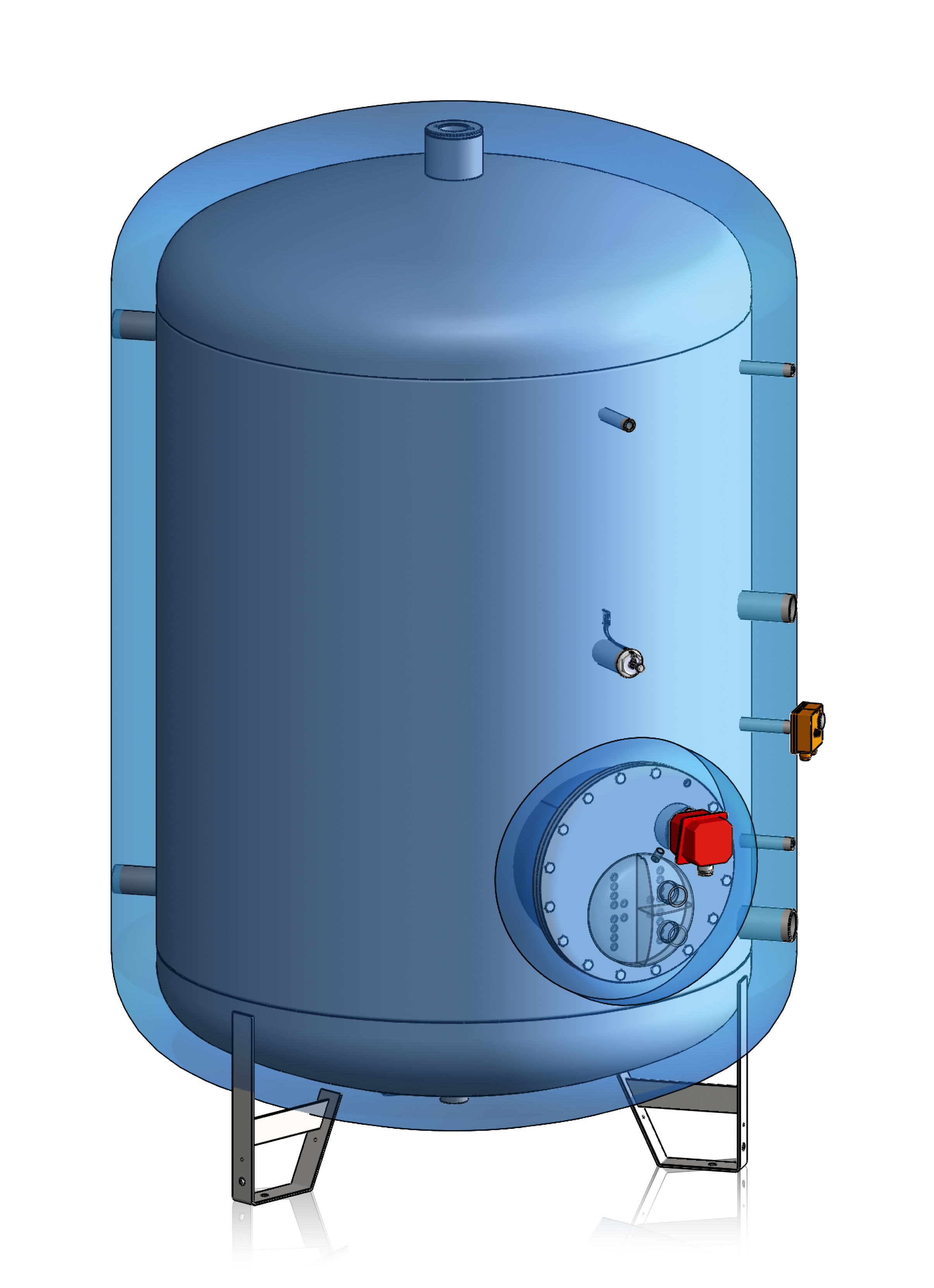

DUAL ENERGY DHW TANK

ELECTRIC IMMERSION HEATER AND U-TUBE HEATER

300 to 10 000 Litres

CE compliance

2014/68/UE

2014/35/UE

Tubular heaters

Immersion heaters or electric cartridges

"RC" internal coating (WRAS approved material)

Stainless steel AISI 316L tank

The dual energy cylinder (electric immersion heater and U-tube heater) is a solution which combines multiple energies to optimise operating costs (for example, heating from a hot water heating circuit during the winter and electric elements in during the summer). It is designed for all types of semi-instantaneous or total accumulation domestic hot water (ECS) production systems for use in residential properties or industrial premises.

It amasses a reserve of water either through an exchanger fixed directly onto the tank and fed by a primary water circuit (hot water for heating), low pressure vapour or any energy recovery system, or thanks to an electric immersion heater.

The volume is sufficient to meet peaks in consumption without temperature fluctuations. With an immersion heater located in the top section of the device (optional integrated loop heater kit), you can quickly replenish hot water reserves in accordance with set point temperatures, providing additional power, which is necessary to meet peaks in demand. The dual energy heater is available with four different types of tank to meet all needs:

Carbon steel

Type of coating |

RC851 |

RC951 |

Capacity |

0.3 à 10 m3 |

0.3 à 10 m3 |

T° max |

85°C |

95°C |

Duration of T° max |

Constant |

Peak |

Acier inoxydable

Nature of stainless steel |

316 L stainless steel |

Capacity |

0.3 à 10 m3 |

T° max |

95°C constant |

Special resistance to chlorinated shocks |

++ |

Partners

Partners